Introduction

Water tank trucks play a crucial role in various industries, including construction, agriculture, and firefighting. These specialized vehicles are designed to transport and distribute large quantities of water to remote or hard-to-reach locations where access to water sources may be limited. Water tank truck operations require careful planning, skilled personnel, and adherence to safety protocols to ensure efficient and safe delivery of water. In this article, we will explore the key aspects of water tank truck operations, including equipment and maintenance, operational procedures, safety considerations, and best practices to maximize efficiency and safety.

Equipment and Maintenance

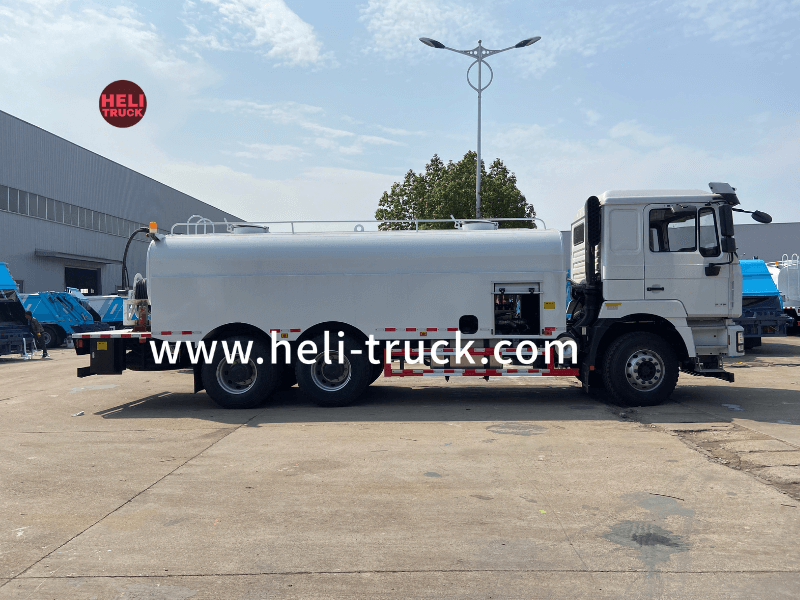

Water tank trucks come in various sizes and configurations to meet different needs and requirements. Common types of water tank trucks include rigid tankers, articulated tankers, and trailer-mounted tankers. Rigid tankers are self-contained units with a fixed tank mounted on a chassis, while articulated tankers consist of a tractor unit pulling a separate tank trailer. Trailer-mounted tankers are standalone units that can be towed by a suitable vehicle.

Proper maintenance of water tank trucks is essential to ensure reliable performance and longevity of the equipment. Regular inspections should be conducted to check for signs of wear and damage, such as leaks, cracks, or corrosion. The tank and associated components, such as pumps, hoses, and valves, should be inspected for proper functioning and cleanliness. Routine servicing of the engine, transmission, brakes, and other mechanical systems is also necessary to prevent breakdowns and ensure safe operation.

Operational Procedures

Efficient water tank truck operations require careful planning and coordination to meet the specific needs of each job. Before starting a water delivery, operators should assess the site conditions, including access points, terrain, and water source availability. Routes should be planned to minimize travel distance and time while ensuring safe and legal operation on public roads.

Loading and unloading procedures should be carried out according to established protocols to prevent spills, contamination, or injuries. Water should be sourced from approved sources and treated if necessary to meet quality standards for the intended use. Operators should follow proper loading and unloading techniques to maintain stability and prevent overloading of the tank.

Safety Considerations

Safety is a top priority in water tank truck operations to protect personnel, equipment, and the environment. Operators should be trained in safe driving practices, including defensive driving techniques, load securement, and emergency procedures. Seat belts should be worn at all times, and speed limits should be observed to prevent accidents and injuries.

Proper signage and lighting should be used to increase visibility of water tank trucks on the road and at job sites. Reflective tape, warning flags, and flashing lights help alert other motorists and pedestrians to the presence of the vehicle and reduce the risk of collisions. Operators should also be aware of overhead obstructions, low-hanging branches, and other hazards that may impede safe operation of the truck.

Best Practices

To maximize efficiency and safety in water tank truck operations, consider the following best practices:

1. Regularly inspect and maintain the water tank truck to ensure optimal performance and reliability.

2. Train operators in safe driving practices, loading and unloading procedures, and emergency response protocols.

3. Plan routes and deliveries to minimize travel distance and time while ensuring compliance with regulations.

4. Use proper signage and lighting to increase visibility of the water tank truck on the road and at job sites.

5. https://www.heli-truck.com/howo-5m3-street-sweeper-truck/ spill prevention and containment measures to protect the environment from potential leaks or spills.

Conclusion

Water tank trucks are essential vehicles for transporting and distributing water in various industries. By following proper equipment and maintenance procedures, operational protocols, safety considerations, and best practices, operators can maximize efficiency and safety in water tank truck operations. Adherence to these guidelines not only ensures reliable performance of the equipment but also protects personnel, equipment, and the environment from potential risks and hazards. By prioritizing safety and efficiency, water tank truck operators can deliver water effectively to support critical operations and projects.